Research

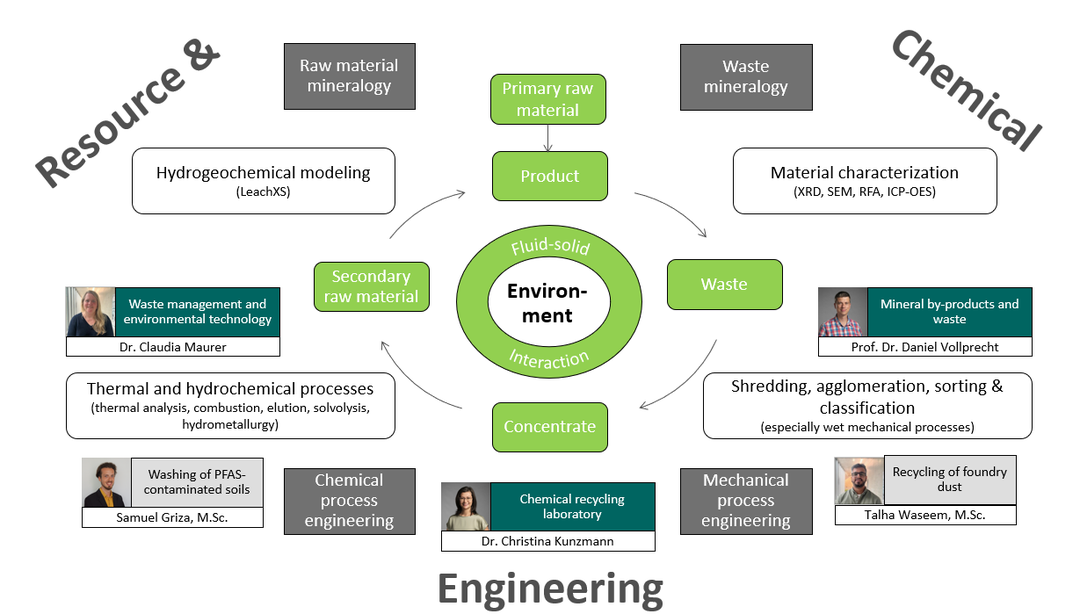

The central theme of our research is the interaction between solids and fluids, especially between materials and the environment. This includes both the targeted dissolution of components of composite materials (solvolysis) and the extraction of valuable materials (hydrometallurgy) as well as the investigation of the undesired release of heavy metals into the environment (leachability) and corrosion. This leitmotif is embedded in an anthropogenic material cycle that represents the entire life cycle of a product. We use methods from various scientific disciplines (waste management, mineralogy, chemistry, process engineering, environmental engineering, materials science) to investigate materials throughout their life cycle, using individual units, analytical equipment and computer programs. The Chemical Recycling Laboratory (Dr. Kunzmann) forms the heart of the department and the interface between the two professorships for Resource and Chemical Engineering (Prof. Vollprecht) and Chemistry of Materials and Resources (Prof. Weihrich, own website). The Waste Management and Environmental Technology working group (Dr. Maurer) deals with reactions between materials or waste on the one hand and liquids or gases on the other. The focus of Prof. Vollprecht's work is on mineral by-products and waste, with a focus on the form of binding, mobility and removal of pollutants.

Mineral by-products and waste

Inorganic non-metallic materials (rocks, ceramics, glasses, binders, ashes, slags, dusts) represent the largest material flows in anthropogenic material cycles. At the same time, they are characterized by a below-average recycling rate, although they can function both as elemental and property raw materials. However, the application of mineralogical methods (phase analysis) and concepts (phase level between the particle and element level) enables sustainable recycling of these materials, as their recyclability depends on the mineralogical binding of valuable and harmful substances. This determines both the separability with processing techniques and the intentional or unintentional release of valuable and harmful substances through interaction with aqueous solutions. The Chair of Resource and Chemical Engineering therefore deals with the characterization of inorganic non-metallic materials along their life cycle, in particular between the “end-of-life” and reuse as recyclate in production processes, and the reactions that occur in recycling processes.

Chair holder

Resource and Chemical Engineering

- Phone: + 49 821 598 - 69130

Email: daniel.vollprecht@uni-auni-a.de ()

In the field of raw material mineralogy, we deal with the characterization of these primary and secondary raw materials with regard to their possible applications, with a focus on industrial minerals, stones and soils as well as recycled and industrial aggregates and waste-based binders. The application of mineralogical processes to materials at the end of their life cycle is referred to as waste mineralogy. These areas require extensive chemical-mineralogical analysis, but also computer programs for modeling solid-fluid interactions.

Chemical recycling laboratory

The chemical recycling laboratory includes chemical and mineralogical analysis such as XRF, ICP-OES and XRD as well as process engineering equipment for coarse and fine comminution, separation of materials and thermal and chemical treatment.

Laboratory manager

Resource and Chemical Engineering

- Phone: +49 821 598 - 69119

Email: christina.kunzmann@uni-auni-a.de ()

When materials accumulate as waste, however, they are often present as mixtures (composites & bulk materials) and must therefore first be separated from each other, for which the area of mechanical process engineering is to be established within the RCE. The materials researched at the RCE are always composites, whereby the composite character can be deliberately generated by a technical process (e.g. fiber composites) or inevitably created in industrial plants (e.g. waste incineration plant bottom ash). Units for coarse and fine comminution of brittle and ductile materials are to be procured for the mechanical disintegration of these composites. As an alternative to conventional methods, electrodynamic fragmentation is to be used, as this enables the separation of waste incineration grate ash along phase interfaces, for example, and is therefore particularly suitable for the composite materials that are the focus of the MRM. The separation of materials includes classification and sorting processes. A screening machine, which can be operated both wet and dry, is available for classifying materials. For sorting, both dry (e.g. wind sifter) and wet sorting (e.g. flotation) units are available or are being procured. It is planned to embed the recycling laboratory in the KI production network.

In mechanical process engineering, concentrates of individual recyclable materials are produced that often cannot be further treated mechanically. For this reason, chemical process engineering is to be established as a second area at the RCE in order to subject the mechanically treated materials to chemical reactions and return them to production processes as secondary raw materials. Individual components are either converted into a liquid state through dissolution processes or into a gaseous state through thermochemical processes, while others remain in a solid state. However, thermochemical processes also include the conditioning of ashes and slags with the aim of minimizing the leachability of heavy metals and maximizing hydraulic activity, and it is precisely this coupling of thermochemical and hydrochemical processes that is a focus of our research. During thermochemical treatment steps, such as waste incineration or the remelting of ashes and slags, specific mineral phases are formed that subsequently influence the leachability of heavy metals. Hydrochemical processes include solvolysis, i.e. the targeted dissolution of material components, e.g. organic components of composite materials, by acids, alkalis, complexing agents or ionic liquids. Hydrochemical processes also include leaching processes, which limit the recyclability of mineral by-products and waste

Waste management and environmental technology

The Waste Management and Environmental Technology working group deals with selected aspects of wastewater and waste treatment, in particular the recycling of inorganic and organic residues from industrial or waste treatment processes, such as fermentation residues from the fermentation of biogenic waste or recyclates from the recycling of resin-bonded grinding tools. Other focal points, such as the research and further development of recycling technologies for critical metals, the use of artificial intelligence in waste management, the assessment of the environmental impact of waste management, the further development of soil washing in the field of contaminated site research and the use of flotation and selective leaching processes for the recovery of metals from fine-grained waste, are currently being developed.

Research associate

Resource and Chemical Engineering

- Phone: +49 821 598 - 69135

Email: claudia.maurer@uni-auni-a.de ()